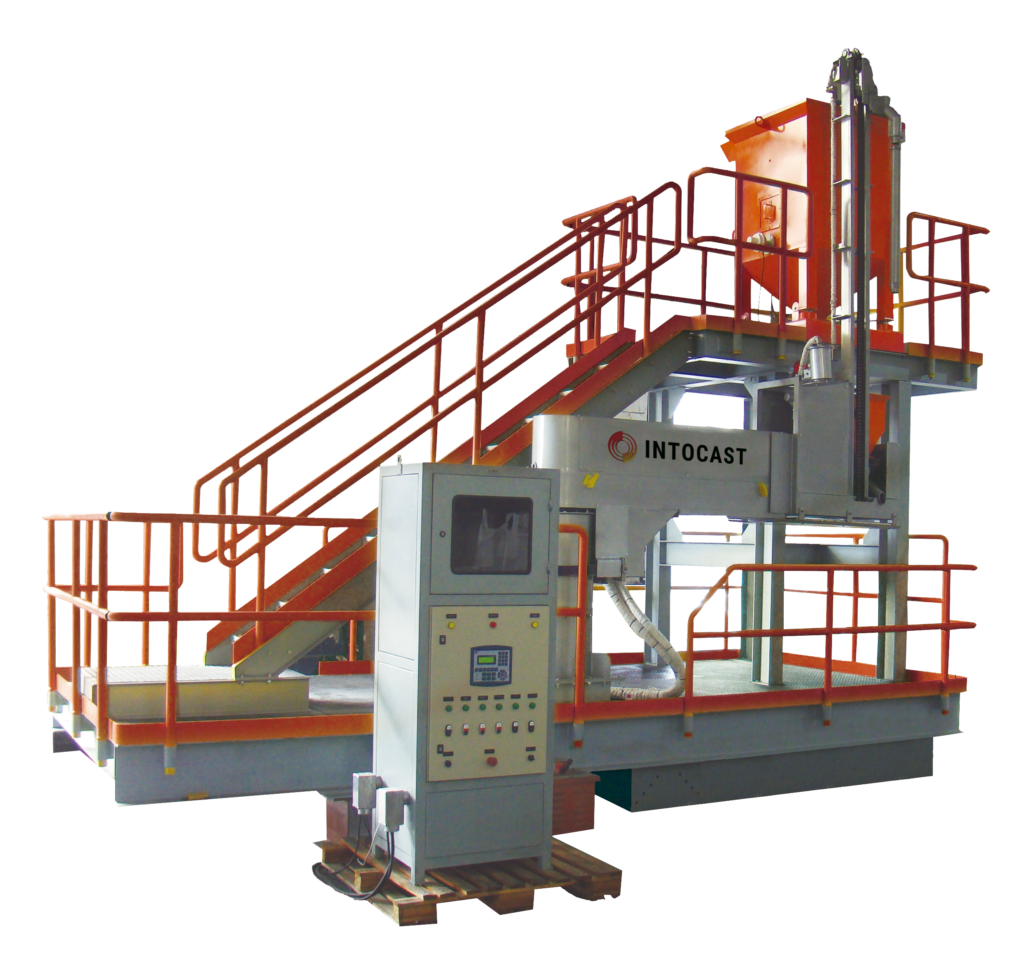

Our Schiebersand filling device for ladles

CARBOOX – member of the INTOCAST GROUP OF EXPERTS - offers a tailor-made filling device for Schiebersand ladle well fillers. This facility assists in minimizing risks for man and machine while contributing to lifting ladle free-opening rates. The filling device features sensors, frequency inverters, filling level controller and PLC systems to guarantee process control and safety as well as precision with material filling events. This reduces the operator's exposure to high temperatures and workplace hazards. Reconcilability of addition processes by video data capturing systems is provided.

Our products and applications in the video

Our Schiebersand filling device for ladles in horizontal and inclined position

INTOCAST has developed a technology that allows ladles to be filled with Schiebersand well filler while in horizontal and inclined position. The system consists of a supervisory control part with camera image magnification selector to be used for video data capturing and an adjustable arrangement for accurate well filler additions.

System for filling well filler from ladles in an inclined position

Advantages of INTOCAST equipment

Common features

- Tailor-made

- User-friendly

- Enhances work safety

- Minimum maintenance requirements

- Guaranteed stable and homogeneous additions

- Semi-automatic systems, filling within 1,5‒2 minutes

- Supports increase in spontaneous opening rates

Reliable sand filling

Special silo characteristics:

- Pneumatic opening mechanism

- Vibration softening to prevent segregation

- Entry screen to prevent ingress of foreign objects

- Low-level alarm system

- Electronically pulsed dosing valve

- Sand heating system for moisture reduction

Process control

- Control panels with PLC technology

- Accurate filling by means of frequency inverters

- Supervisory systems with 32-times magnification

- Reconcilability of addition processes by video data capturing systems

Occupational safety

- Plant operator’s exposure to operational risks and hazards is reduced

- Visual safety system provides warning lights and decreases accident risks

- Interlocks prevent unplanned interferences during sand filling activity

Additional functions (optional)

- Laser guidance device during lifting activities for accurate steel ladle positioning for sand filling

- Wireless video process supervision with crane driving activities

- Temperature measuring device for tap hole brick