Slag conditioners at optimum conditions

We supply slag conditioners as primary or secondary products from our supply centers - worldwide, naturally. We offer a wide range of economically attractive solutions. Of course, we are happy to help you decide!

Our slag conditioners

- Magnesite-based products with different ignition losses (30%, 10%, 5%), available in different grain sizes depending on the type of addition and requirement

- Dolomite-based products with different ignition losses (50%, 1%) and available in different grain sizes depending on the type of addition and requirement

- Alumina media (bauxite-based, other primary materials), recycled residues with and without metallic aluminum content

- Synthetic slags as recycled or specially manufactured products (sintered or pre-melted)

The main reason for using magnesitic and dolomitic slag conditioners is the enrichment of slags with basic oxides. They are needed to perform metallurgical work and for the protection of refractory linings. Pneumatically conveyable slag conditioners with higher LOI percentage also provide ideal support in slag foaming.

Calcium-aluminate slag conditioners create favorable conditions for speeding up reaction rates in metallurgical work. Besides improving reactivity, they also increase the slag’s capacity for scavenging molten impurities.

TOPEX MgO-CSC

TOPEX MgO-CSC is a semi-calcined magnesite product supplied in briquette form. At temperatures in excess of 900 °C it disintegrates while releasing CO2 and H2O and turns into highly reactive MgO. Process technology advantages that can be derived from its chemical composition as well as the physical properties of TOPEX MgO-CSC are documented in a patent. Regarding the generation of foamy slags, results of operation campaigns have confirmed the outstanding superiority of this product. This also applies to slag splashing where TOPEX MgO-CSC is preferred compared to traditionally used dolomitic lime.

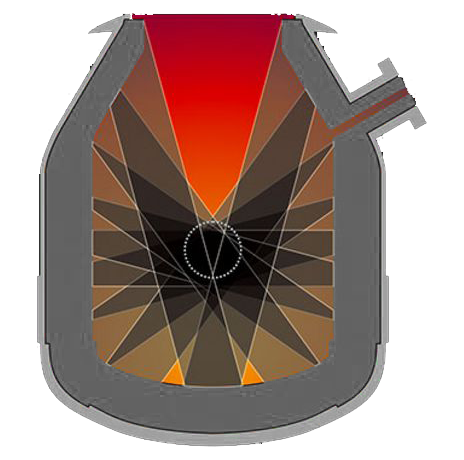

Coating of the refractory lining with the addition of TOPEX MgO-CSC

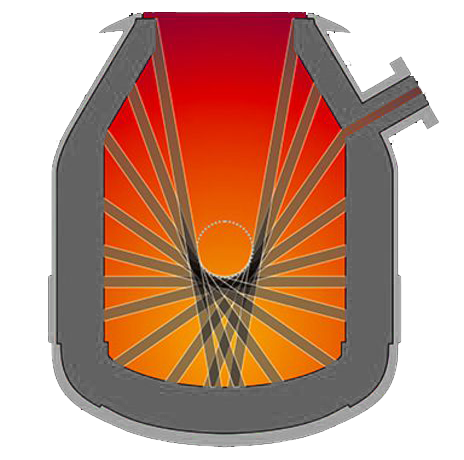

Traditional coating of the refractory lining without the addition of TOPEX MgO-CSC