More and more steel producers rely on INTOCAST as a competent partner

Our steelmaking products are the core business of the INTOCAST GROUP OF EXPERTS.

For example, as the oldest member of the INTOCAST GROUP OF EXPERTS, DOLOMITE FRANCHI is able to draw on a hundred years of expertise.

Permanent research, further development of our refractory products as well as first-class all-round service make the INTOCAST GROUP OF EXPERTS a valuable partner for customers in the steel industry worldwide.

Primary metallurgy

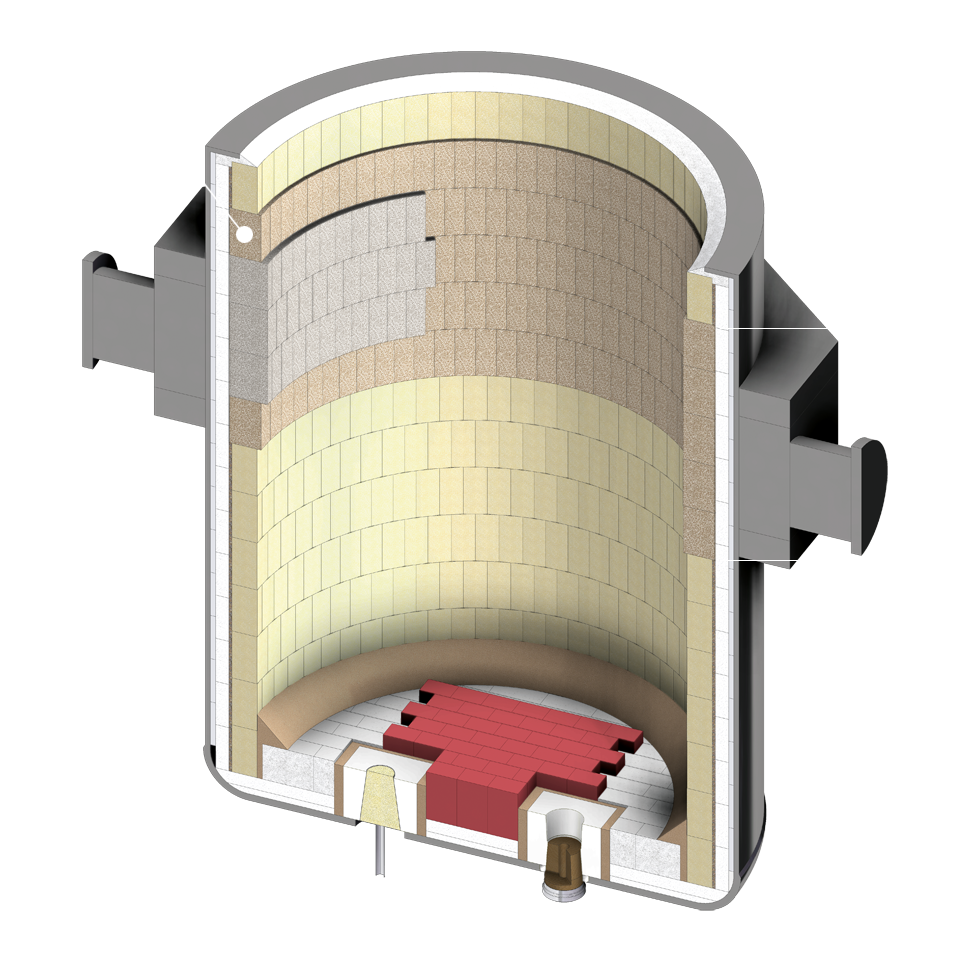

Refractory linings of modern converters and electric arc furnaces usually consist of mag-carbon bricks. INTOCAST offers their customers not only highest quality materials but also appropriate designs: we manufacture made-to measure products for reliable lining performances and long service lives. Over and above, we offer our INFINITY and ULTIMAX maintenance products for even lining wear, ideal tools to reliably prolong the service life and operational stability of the vessels.

High-quality linings, in conjunction with perfectly matched maintenance products, guarantee minimum downtime. A comprehensive service plan complemented with high-tech equipment provides for maximum operational availability of melting units. Talk to us!

Our products and applications in the video

Secondary metallurgy

Steel teeming ladle

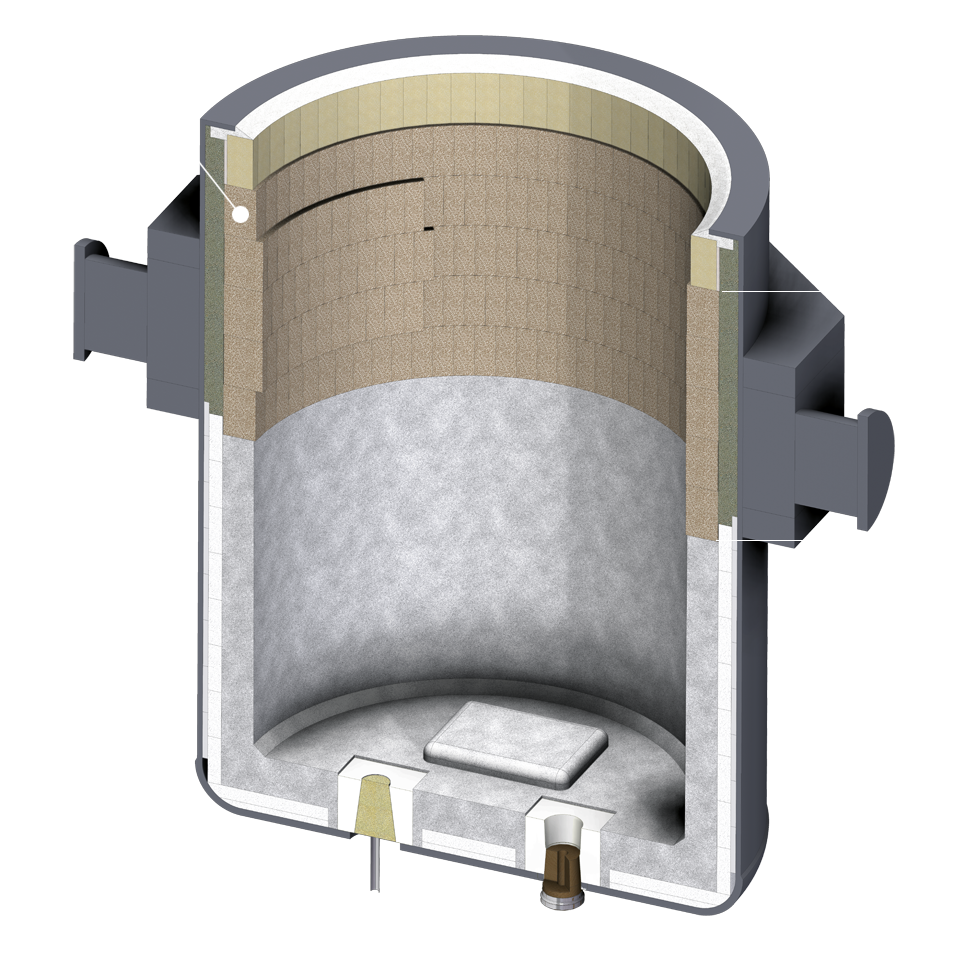

The production of steel is a complex affair. For example, extensive bottom purging activities ensure that the steel stays in the ladle longer. In the field of steel production, the heating processes in pan furnace operations and vacuum treatment are also significant factors. As such, optimally coordinated linings of the steel foundry ladles are a basic prerequisite for the economical production of high-quality steel. The experts at INTOCAST know this. This is why we develop an individual concept for the operation of integrated steel mills, mini-mills, and for the production of stainless steel for each customer.

Our products and applications in the video

Lining options

Classic lining with mag-carbon, dolomite or AMC bricks

In hybrid ladle linings, INTOCAST combines classic brick installations with monolithic refractory lining technology. Ladle floor and/or side walls are lined with self-flowing concrete or thixotropic material. The slag line is prepared with traditional mag-carbon brick masonry.

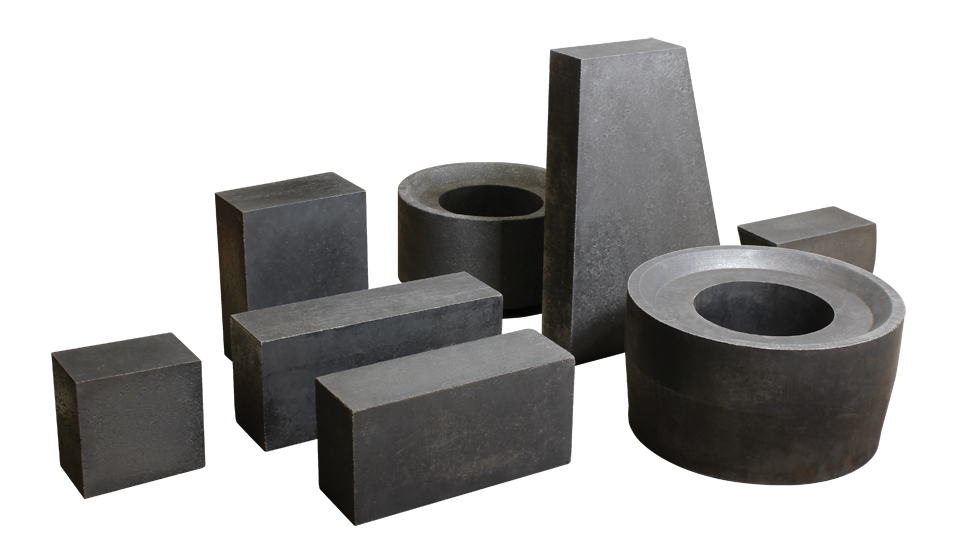

Shaped refractory products

“Form follows function“ is a design guideline also applicable to our refractory products. INTOCAST offers a wide range of shaped refractory products in line with your requirements. Our portfolio covers simple straights, taphole end bricks, taphole sleeves all the way to metal cased keys in numerous formats and versions. Of course, we manufacture products according to your individual requirements. Contact us, we look forward to receiving your call or mail!

Shaped INTOCAST refractory products

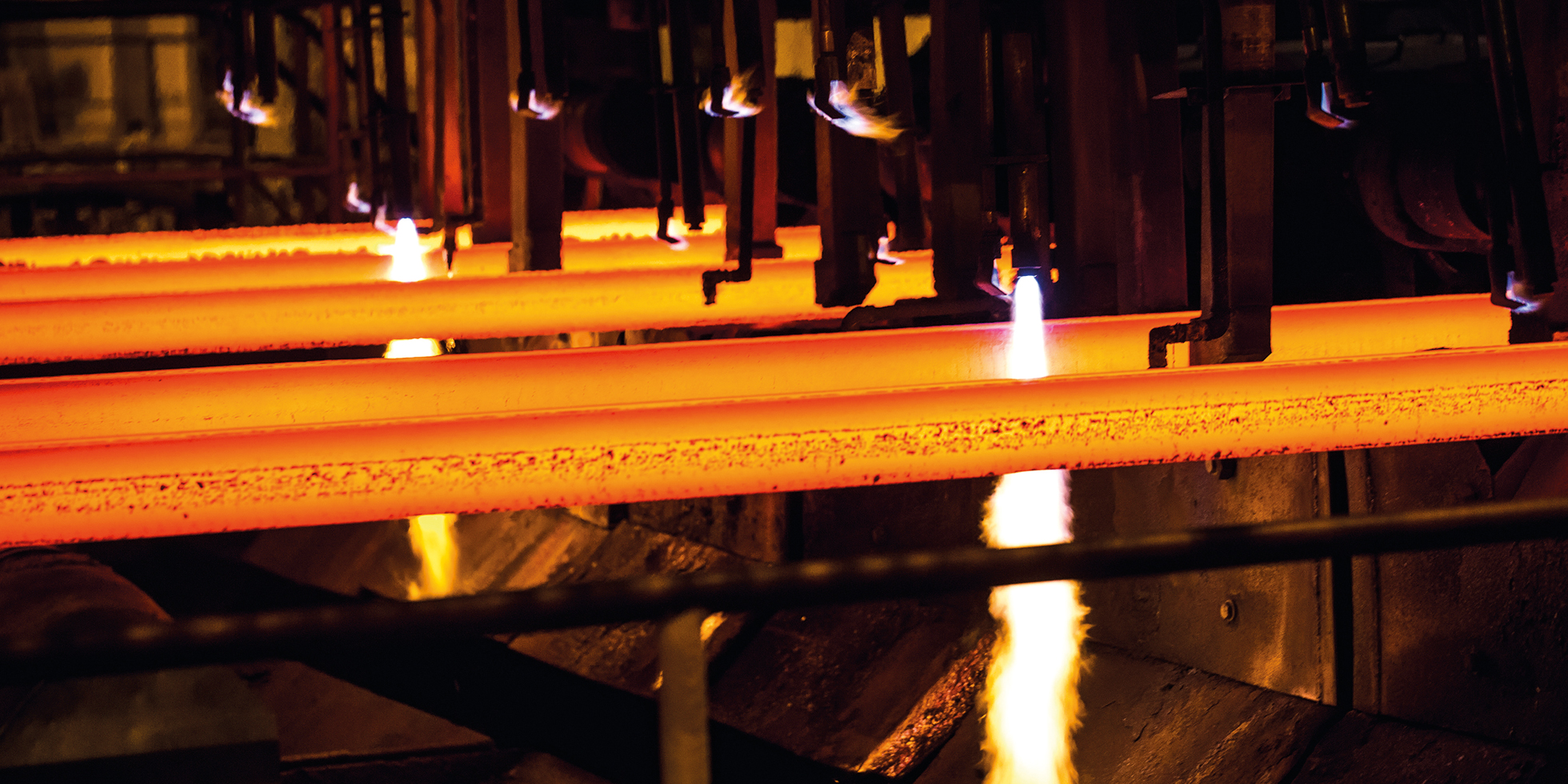

Continuous casting

When it comes to continuous casting, the experts at INTOCAST make it all possible for you. We offer durable safety linings for your tundish with optimum insulation properties as well as finished components and working linings. Of course, the scope of delivery includes the provision of machines as well as the skilled essential personnel.

Are you looking for further opportunities to optimize your processes and costs? Look no further, we have got it right here: outsourcing of your entire tundish management! INTOCAST offers a worldwide accredited system for tundish management. Excellence in research and the development of customized products have led INTOCAST to be one of the technology and market leaders in this field. Carbon-free tundish lining materials are part of the product portfolio as much as highly insulating slurry spraying materials and consumption-optimized dry vibratable mixes.

With the “Endless Recycling System”, INTOCAST saves valuable resources by applying state-of-the-art material processing technology. Products recovered from spent linings are returned to the refractory making cycle, assisting in care for the environment. The introduction and implementation of MAPEKO’s highly efficient tundish Soft Drying System FOEHN® further contributes to environmental considerations of the INTOCAST GROUP OF EXPERTS.