- Home

- Company

- Products & Applications

- Overview

- Refractories

- Casting Solutions

- Well Filler

- Equipment Engineering

- News

- Career

- Contact

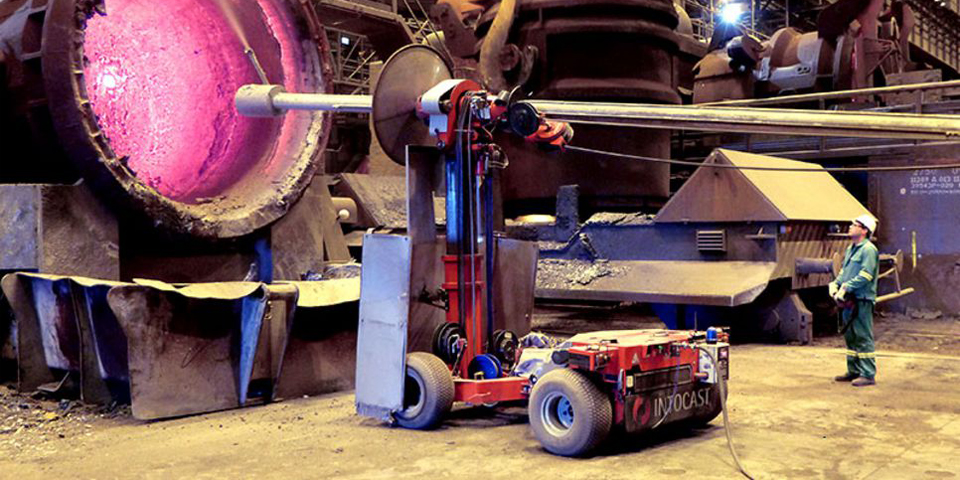

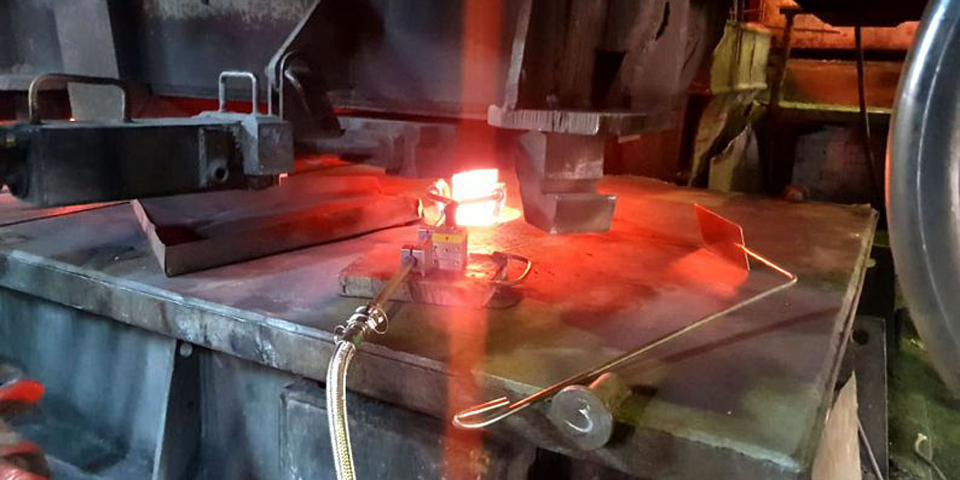

Our tailor-made

system engineering

We love challenges. That’s why we enjoy building new plant systems so much. Specialized machine and plant engineering is the prerequisite in applications of technologically demanding refractory products. We as INTOCAST develop and build tailor-made engineering systems for our customers perfectly matched with their needs ‒ for an extended service life and performances with maximum added value. Curious? Well, contact us, we will gladly provide you with a proposal and quotation.